OWM, Case Studies

ASRS- AUTOMATED STORAGE AND

RETRIEVAL SYSTEMS ASRS

When high volumes of inventory move in-and-out of manufacturing facility or from distribution centers Automated Storage and Retrieval Systems ASRS players terrific role. Warehouse and DC mostly utilize ASRS for goods-to-Person picking, dynamic replenishment and Order consolidation and for manufacturing facility ASRS mostly used for Sequence Buffering, Kitting Operations, Work in Progress (WIP) or storage of a finished products.

ASRS- Case Study

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Rerum accusantium non in eos illum officiis voluptatibus sint? Laboriosam, quod unde, optio sequi dolor dignissimos excepturi voluptatibus accusantium ipsum quo rerum! Lorem ipsum dolor, sit amet consectetur adipisicing elit. Animi voluptas natus fugit eos reiciendis in quia, laudantium eaque autem maiores voluptatem. Ipsam dolorum amet assumenda sequi quidem laudantium, obcaecati fugit.VStore- Vertical Storage System

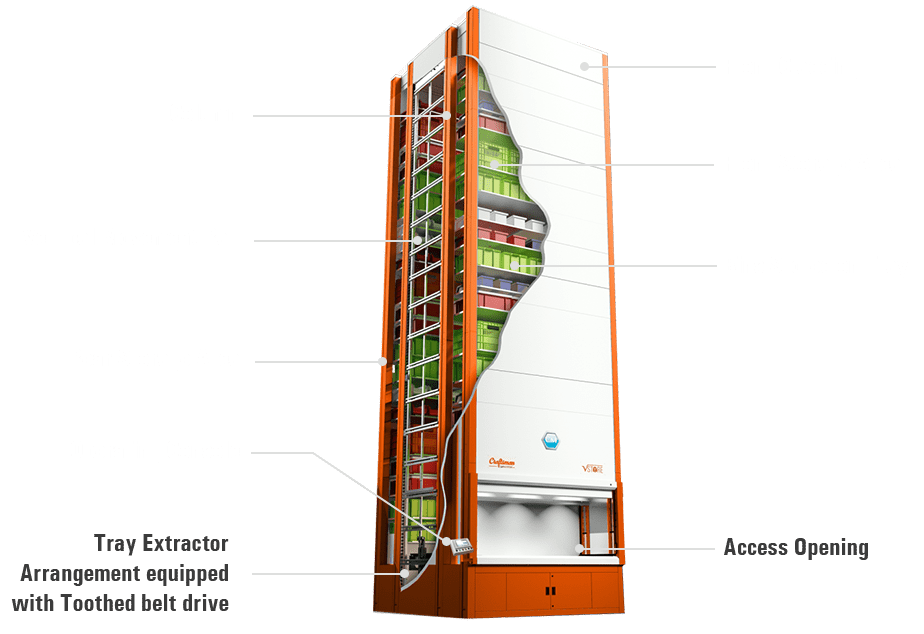

Our vertical Automated storage and retrieval systems with a small footprint, high density, VStoreTM(Vertical Lift Module) makes maximum use of floor and vertical space and offers cost-effective, efficient, quick, and ergonomic solutions to meet your storage and retrieval needs. VStore is a Vertical Lift Module type ASRS completely in-house developed and completely indigenous manufactured in our facility in Coimbatore.

The possibilities of VStore are unlimited. This type of Automated storage and retrieval system can be deployed in various industries such as automotive, electronics, manufacturing, health-care, retail, logistics and warehousing. Wherever items need to be stored with effective usage of space and retrieved quickly, VStore provides the optimum solution.

Vstore- Case Study

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Rerum accusantium non in eos illum officiis voluptatibus sint? Laboriosam, quod unde, optio sequi dolor dignissimos excepturi voluptatibus accusantium ipsum quo rerum! Lorem ipsum dolor, sit amet consectetur adipisicing elit. Animi voluptas natus fugit eos reiciendis in quia, laudantium eaque autem maiores voluptatem. Ipsam dolorum amet assumenda sequi quidem laudantium, obcaecati fugit.

3PL- LOGISTICS

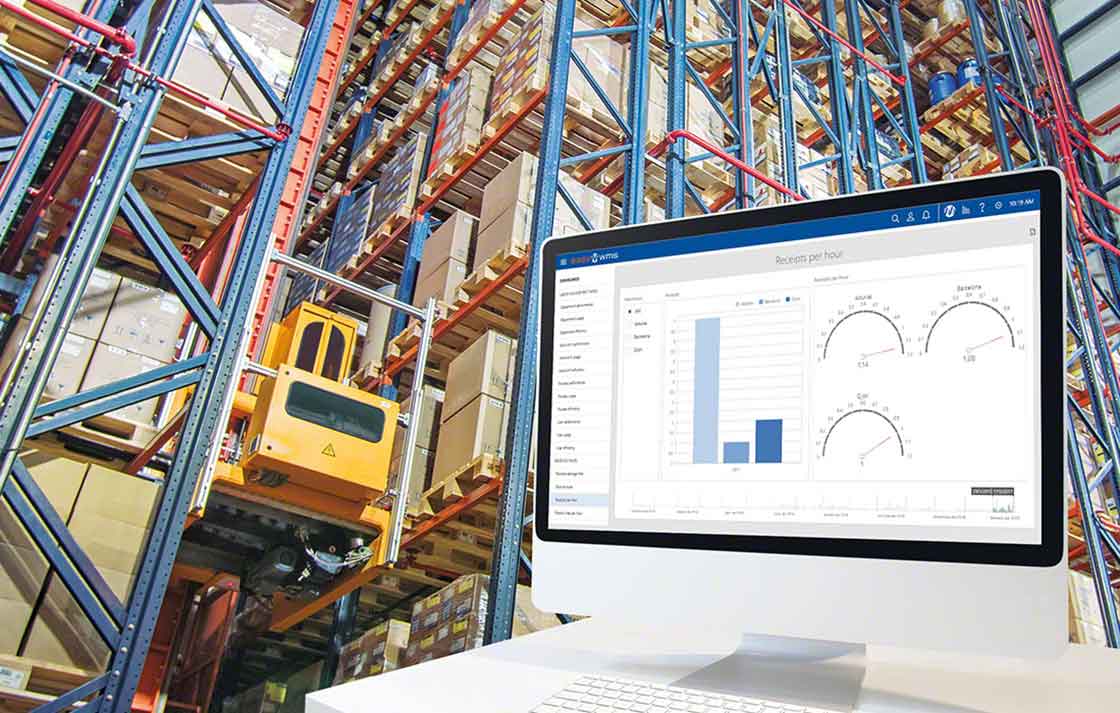

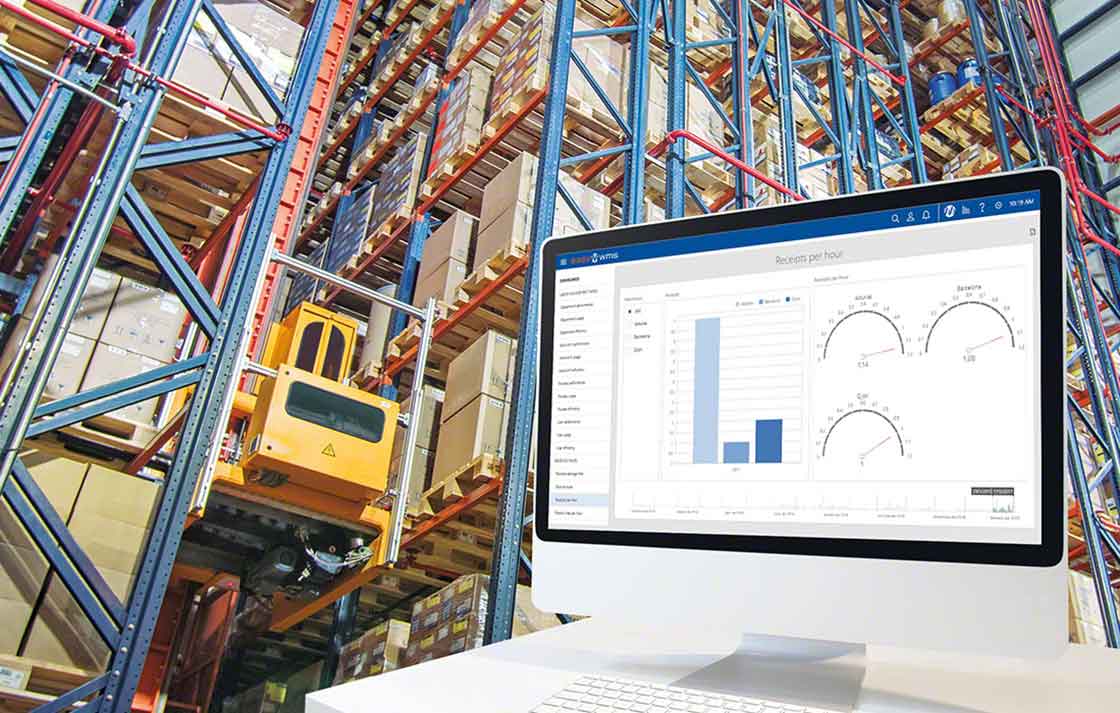

We store and manage your inventory in our strategically located state-of- the-art fullfillment centers giving flexibility to cater the different needs of customers irrespective of the industries they belong.Powered by cutting-edge technology, we ensure that your storage, requirements and inventory management needs are met while providing real-time visibility to help you control your stock levels, streamline purchases and improve your order cycle time.

If you are looking to optimize your existing owned warehouse or storage facility, then our supply chain experts can fully manage your facility, minimize waste, create better space utilization, select the right equipment, streamline operating expenses, and increase service standards. We have been Runing on the Best ERP(SAP) and WMS which is not only optimizing our processes but also provide real time tracking and reporting to our existing customers about their storage.

3PL- Case Study

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Rerum accusantium non in eos illum officiis voluptatibus sint? Laboriosam, quod unde, optio sequi dolor dignissimos excepturi voluptatibus accusantium ipsum quo rerum! Lorem ipsum dolor, sit amet consectetur adipisicing elit. Animi voluptas natus fugit eos reiciendis in quia, laudantium eaque autem maiores voluptatem. Ipsam dolorum amet assumenda sequi quidem laudantium, obcaecati fugit.

In Plant Logistics

To seamlessly integrate our customer's productions process with their external supply chain, OWM In-Plan Logistics offerings comprises a wide range of services and activities within our customers manufacturing plant and their internal central or external warehouse facilities.

Our In-Plant Logistics services cover the movements within the manufacturing plant and for a variety of customer's sites ranging across plants, ports, terminals and yard. To facilitate the internal logistics, and for utmost utilization, we overtakes customers owned assets and also provide materials handling equipments like VNA machines, forklifts, loaders, EOT and other cranes, Trucks and Trailers, facilities-receipt, in-plant warehousing, production line feeding. OWM In-Plant services will enable you cut costs, enhance the productivity, and get the maximum return on your most valuable resources- people. Our experts assist to make your people more productive and focused, your organization become efficient enough to address business competition, Following the SOP Standardization, Quality, Safety and SLA is part of our culture, we continuously invest considerable time building reliable processes, practice, technology and training, to achieve the goal of zero defect and zero stoppages.

In Plant Logistics- Case Study

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Rerum accusantium non in eos illum officiis voluptatibus sint? Laboriosam, quod unde, optio sequi dolor dignissimos excepturi voluptatibus accusantium ipsum quo rerum! Lorem ipsum dolor, sit amet consectetur adipisicing elit. Animi voluptas natus fugit eos reiciendis in quia, laudantium eaque autem maiores voluptatem. Ipsam dolorum amet assumenda sequi quidem laudantium, obcaecati fugit.

Warehousing

OWM provides end to end warehouse operation services that have 25% min. cost efficiency, excellent operational efficiency, high level of customer satisfaction, and impressive inventory accuracy of International benchmarking level. Our team promotes High Health Safety and Environment performances with seamless support to maintenance and manufacturing process

A well and systematically run warehouse operation is always a crucial subject for your business competitiveness. You need highly talented team to observe day to day challenges and introduce ability to optimize overall your warehouse operations, giving you visibility across the warehouse and goods movement, introduces big potential cost-saving methodologies by improving continues process, adapting technologies and performing warehouse operations with best suited material handling equipments. We walk towards you to operate your complete warehouse with industry best & talented professionals, long expertise, well-suited technologies, industry best practices and widely used equipments, we take care of your warehouse right from receiving inbound, inspections, put away, cycle count, picking and dispatching internally or for outside customers.

Warehousing- Case Study

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Rerum accusantium non in eos illum officiis voluptatibus sint? Laboriosam, quod unde, optio sequi dolor dignissimos excepturi voluptatibus accusantium ipsum quo rerum! Lorem ipsum dolor, sit amet consectetur adipisicing elit. Animi voluptas natus fugit eos reiciendis in quia, laudantium eaque autem maiores voluptatem. Ipsam dolorum amet assumenda sequi quidem laudantium, obcaecati fugit.